About DENIOS

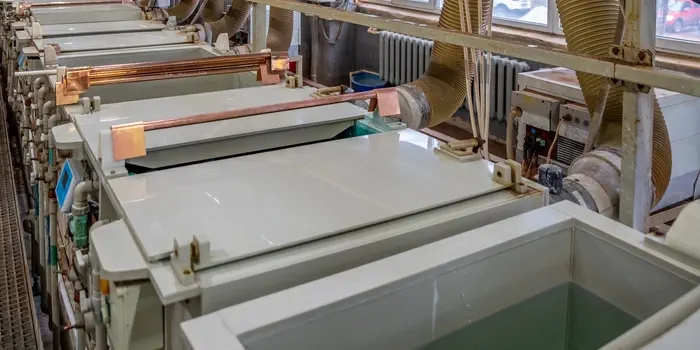

With over 30 years of experience as a developer, manufacturer, and supplier, DENIOS has established itself as an expert in the storage and handling of hazardous materials. The company is committed to delivering high-quality, functional products and comprehensive solutions aimed at safeguarding individuals and preserving the environment in daily operations. Alongside an extensive array of services and maintenance options, businesses gain from the profound expertise offered by the DENIOS Academy. This institution imparts knowledge through practical seminars, training sessions, workshops, and webinars that cover essential topics such as hazardous materials, environmental legislation, workplace health and safety, occupational safety, and fire protection.

Mr. Jost, could you elaborate on the daily challenges encountered by DENIOS Sales regarding product configuration?

Ansgar Jost: When discussing hazardous materials storage facilities, we refer to systems that may require an investment of up to one million euros. Proper planning is essential in this regard. The primary emphasis is on the compliant storage of hazardous materials. Typically, depending on the company's size, our customers have a designated fire protection and occupational safety officer.. However, it is important to recognize that these professionals may not be equipped to address new regulations, such as updated fire protection standards, on a daily basis.

Consequently, many customers appreciate having us as their knowledgeable partner and resource. The graphic variant configurator extends beyond mere 3D visualization. During the development of customized solutions, we pose numerous question to our customers. Often, they are unaware of the various technical and legal elements that require examination, as well as the interdependencies involved. For instance, in relation to our core product, the fire protection storage system, we engage in a thorough review of 60 questions with the customer.

The variant configurator plays a crucial role in this process, serving as a guiding tool during discussions that highlights potential errors in the configuration. The 3D representation allows customers to visualize the product's development, thereby clarifying the necessity of our extensive questioning.

What capabilities does your 3D configurator provide in conjunction with SAP for the digitalization of sales processes in this domain?

Ansgar Jost: Ultimately, the customer seeks a completed and operational hazardous materials storage system within their organization. Essentially, they prefer not to engage with the topic in detail. However, it is imperative for us to do so, as thorough planning and adherence to legal requirements necessitate a comprehensive understanding of the subject. With this in mind, it is highly beneficial that we can collectively review the completed system at the conclusion of the meeting. This approach maintains a heightened level of anticipation and facilitates an enlightening moment for the customer, as they come to understand the intricacies of our products. This facilitates a clearer comprehension of the reasons behind the eventual cost of their technical room system, which amounts to X. The transparency of this process is unparalleled.

What feedback did customers and users provide following the launch?

Ansgar Jost: Initially, it was essential for us to provide training for our employees. However, the focus was not primarily on the use of the configurator, as its intuitive design makes it user-friendly. Instead, the training concentrated on hardware handling. For instance, understanding how to establish the connection between the tablet and the projector at the customer's location was crucial. Interestingly, one of our colleagues from the Sales department, who initially had limited IT skills, has now become the most frequent user of the configurator during customer meetings. This transformation can be attributed to that realization that the system significantly aids users by offering guidance and a structured approach. And last but not least, we have received consistently positive feedback from our customers.

Looking ahead, what might the future of digital sales entail, and what visions does DENIOS have?

Ansgar Jost: At DENIOS, we are placing significant emphasis on the service and accessory sectors. In relation to sustainability, this includes initiatives such as incorporating green roofs or wall vegetation in our technical room systems. I consider both the service and accessory components to be aspects that I would naturally expect to be included in the configurator. Firstly, I believe that the configuration process is equally engaging for other products, as it provides immediate visibility of the final product. Additionally, I am of the opinion that the system could facilitate even more direct sales.

In summary, what is your preliminary assessment of the variant configurator and 3D visualization at this stage?

Ansgar Jost: The implementation of the variant configurator in SAP in 2016 proved to be the right decision. This innovation allowed us to shift the weighting of project to standard containers from a ratio of 80 to 20 to a new ratio of 20 to 80. Consequently, other sectors, including production and scheduling, are now completely aligned with the configurator. The configurator has proven to be an invaluable asset for our operations, and the subsequent implementation of 3D visualization represents a natural progression in this regard. Moving forward, we intend to incorporate additional products into the configurator and expand its availability on an international scale throughout DENIOS AG.

It is evident that we will rely on the configurator indefinitely. We acknowledge that this represents a significant investment. We gain advantages from a level of professionalism, competence, and expertise that is unmatched within our competitive landscape.